Tulasi Aero Marine Pvt. Ltd. is a Company promoted by Maj. P.T. Choudary, after his early retirement from the Indian Army, Corps of Engineers, and is duly incorporated under the Companies Act 1956, in Hyderabad.

Main Objective:

Tulasi Aero Marine is collaborating with global leaders in Hovercraft (Air-Cushioned Vehicles) manufacturing, to bring into India cutting-edge technologies and adapt/improve on them. The ompany also aims to work with suitable Shipyards to manufacture Hovercrafts in India under licensing/royalty arrangements as part of the "Make in India" Programme.

In collaboration with M/s ABS Hovercraft Ltd, Tulasi Aero Marine aims to introduce and manufacture world-class composite body Hovercrafts through a Joint Venture / Technology Transfer for the Millennium Award Winning M-10 Hovercraft.

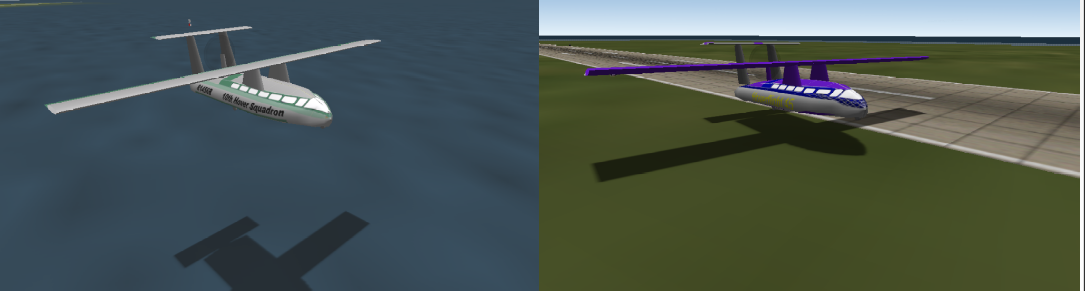

In partnership with M/s Australian Hovercraft, the Company plans to bring both Aluminium and Composite body Hovercrafts and Hoverflights (Wing in Ground Effect Craft) to India.

These vehicles are designed to offer a unique mix of size, speed, range, agility, and amphibious capabilities — all the while maintaining low operational and maintenance costs. Applications include Military, Border Patrolling, Coast Guard, Rescue, Tourism, and Ferry Services.

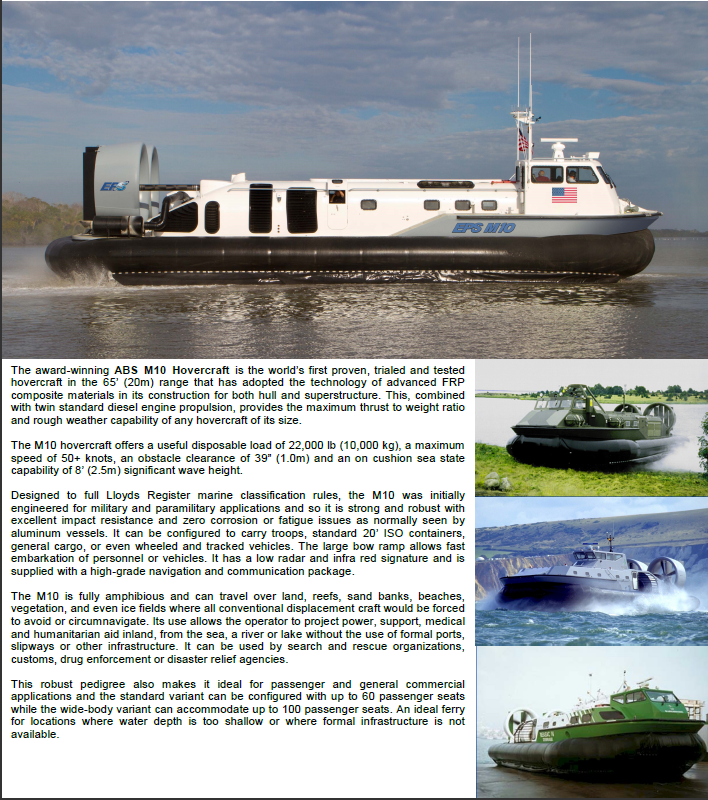

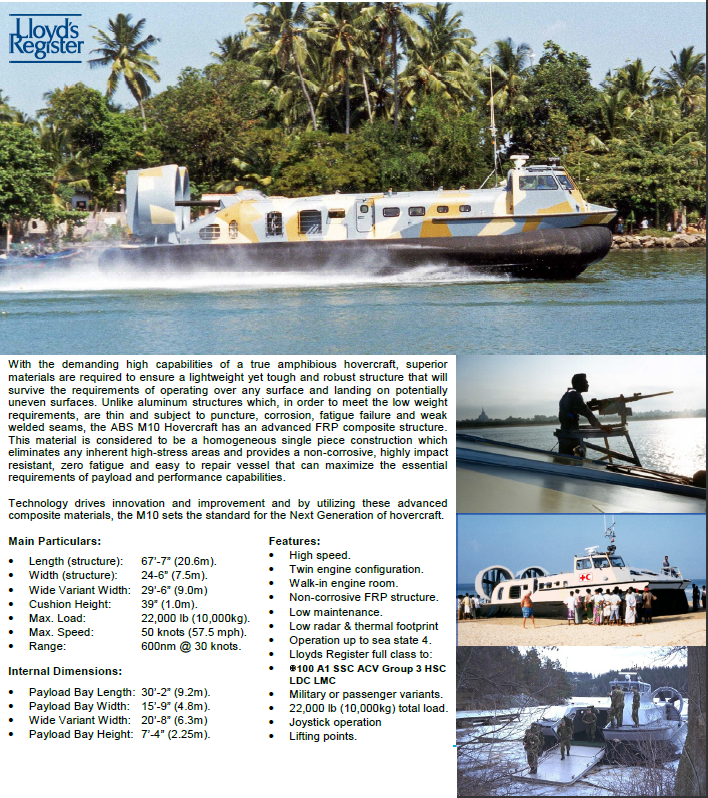

ABS Hovercraft Ltd

Millennium Award Winning Hovercraft M-10

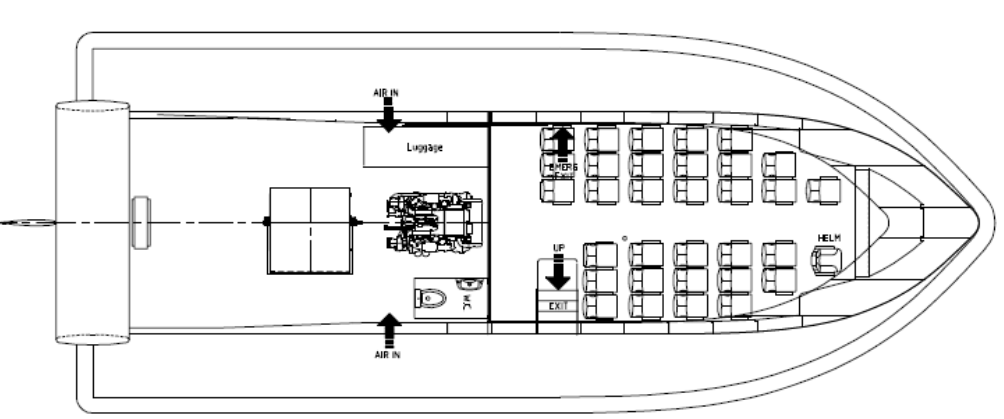

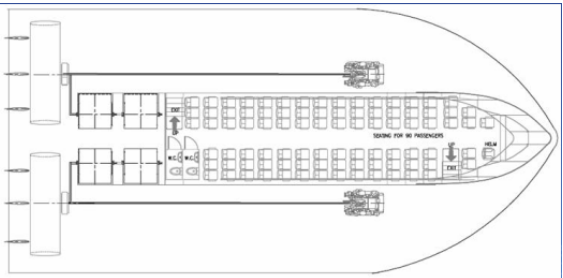

M-10 Passenger, Cargo and Military variants

Australian Hovercraft

Promises silent travel over reefs and high seas

HOVERCRAFT / HOVERFLIGHT 30 / 90

Hovercrafts Operate from Ground / Sand / Ice / Grass and Water.They are truly amphibious crafts.

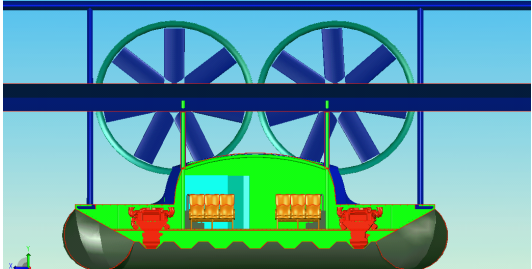

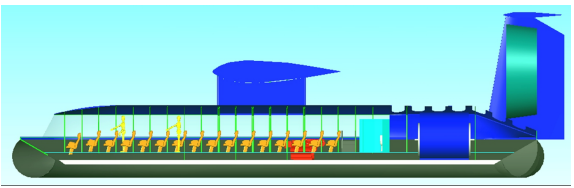

Hovercraft 30

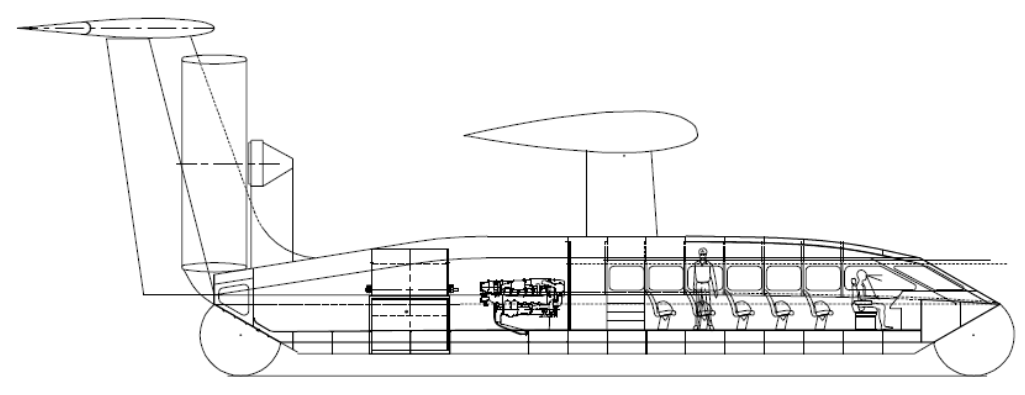

Hovercraft 90

Velocity 90 Hovercraft approximate specifications:

- Length 30 meters.

- Beam 13 metres.

- Max speed 60 knots on dead flat water.

- Endurance - 30 hours at cruising speed. Fuel carried 5400 liters.

- Cargo 15 tones with 12 hours endurance. If we reduce the fuel load, and under Sea state force two condition. Load will be less as the sea state goes upto force 5.

- Will carry about 45 personnel totalling 80 kg each.

- In civilian mode it can carry 90 passengers.

- Aisle in passenger compartment is just over 1 meter.

- Side decks is designed to carry cargo, including cars and trucks. weight should be identical both sides.

- Double doors both port and starboard side to allow large cargo to be carried in the cabin. Normal Door width is 850 mm. Double doors make it 1700 mm. or 1.7 meters

- Distance from cabin to side deck is about 3730 + 500 MM = 4.230 metres.

- Beam is 13 meters. with 500mm added width each side.

- Optional space can be adjusted to fit in additional toilets, pantry, rest-room as may be required by appropriately reducing the number of seats.

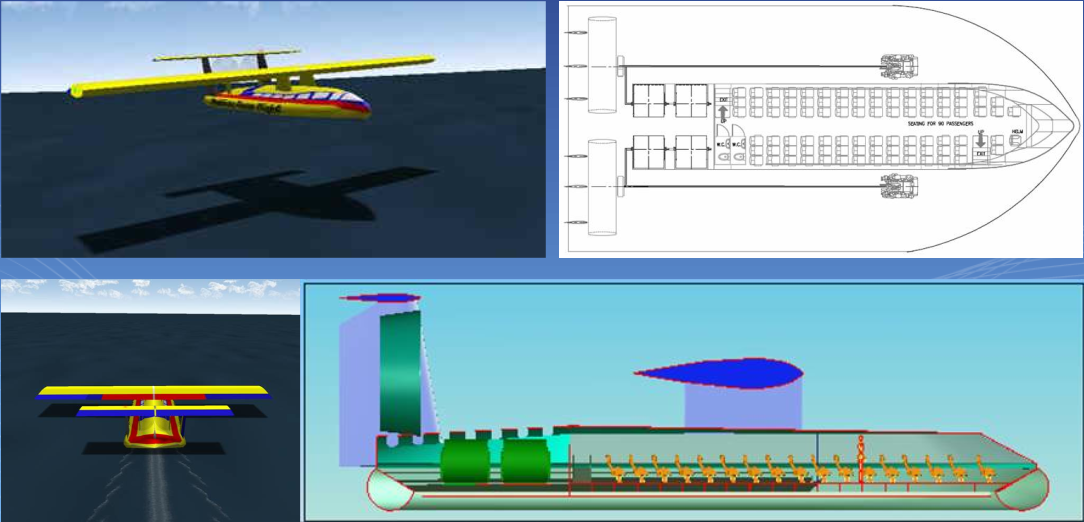

Hoverflights are Hovercrafts with wings and operate with Wing-in-Ground effect and are not only amphibious but are also capable of flying over low obstacles and rocky beaches and also in heavy seas. Hoverflights can travel at speeds upto 75 knots.

A Wing-in-Ground (WIG) effect craft is a high speed, low altitude (about half the wing span) vehicle that uses the Ground Effect to fly just above the surface. It combines features of an aircraft and of ships, offering grater transport efficiency and speed than conventional Hovercraft or other marine vessels.

WIG craft are an increasingly attractive technology for fast, safe and efficient marine/ amphibious transportation .WIG crafts do not need a runway, they can take- off from land or water on any sufficiently large flat surface.

WIG craft carry significant loads and are being considered for various applications including passenger transport, logistics and military uses such as reconnaissance and troop transport/insertion.

Air Cushion provided very gentle Landings on smooth or adverse sea states. In monsoon seas, the hoverflight lands on top of the Swell, in 30 knot Cross winds. Being a Hovercraft, the wings are Horizontal all stages of landing and the heading is adjusted into wind, so the hovercraft slides at any point of the compass to keep its track on top of the Swell.

Hoverflight 30

Hoverflight 45/60/90

WIG craft are approved by the Maritime Safety Committee under MSC/Circ. 1126. Type -A is certified for operation only in ground effect, say about half the wing span.

Hoverflight crafts can be provided with optional features such as retractable wheels, for better operational flexibility and even retractable Skirt, for longer Skirt life.

- 90 Passengers, over sea states up To Force 5.

- Will take off and Land In sea states force 4-6.

- Can take off from Land, Aircraft Runways at sea near sea level, or from resonably flat Grass or firm Sand.

- Silent Propeller Seven Blades.Passengers cannot hear propellers.

- Retractable Landing Wheels on Hoverflights and Hovercrafts. Land on water, taxi to marine ramp, engage Hydraulics to rotate the landing Wheels, wheels power the craft to the resort, park the Hoverflight with wing tip next to resort Entrance.

- Passengers exit craft under wings, Protected from Rain or Hot Sun. Resort/ Hotel staff can take their baggage to their Rooms.

- 90 passenger Hoverflight craft flying 3–10m above sea at

75 knots (140 km/h) in sea states up to 4–6. - Economic and comfortable transport between coastal cities.

- Take-off and landing on sea water, sand, grass, ice, and ground.

- Ideal for flood relief and rescue operations.

- Surveillance capabilities for coastal monitoring.

- Usable for cargo, or a combination of cargo and passengers.

Optional features:

Retractable wheels and skirts to allow flexible operations and extended skirt life.

Specifications:

| Passenger Capacity | 30 / 60 / 90 |

|---|---|

| Speed | 90 knots max, 75 knots average (140 km/h) |

| Take Off | 0–200 meters at 4–25 knots Then: 60–75 knots Total Runway: 1200 meters |

| Diesel Consumption |

30 pax: ~100 L/hr | 0.75 L/km | 1.40 km/L 60 pax: ~200 L/hr 90 pax: ~300 L/hr |

When comparing marine aluminum, prepreg carbon fiber sheets, and prepreg glass fiber sheets in terms of density, strength, and comparable thickness, here’s how they differ:

| Category | Marine Aluminum | Prepreg Carbon Fiber Sheet | Prepreg Glass Fiber Sheet | |

|---|---|---|---|---|

| Density | Density is approximately 2.7 g/cm³. | Lower density, typically around 1.5 to 1.6 g/cm³. | Higher density, typically around 2.0 to 2.5 g/cm³. | |

| Density Comparison | Prepreg carbon fiber sheets have the lowest density, followed by glass fiber sheets, with marine aluminum having the highest density. Therefore, carbon fiber sheets are advantageous in marine applications where weight reduction is critical. | |||

| Strength | Tensile strength typically ranges from 200 MPa to 600 MPa, depending on the specific alloy. | Extremely high tensile strength, typically ranging from 3,500 MPa to 6,000 MPa. | Lower tensile strength compared to carbon fiber, usually between 2,000 MPa to 3,500 MPa. | |

| Strength Comparison | Carbon fiber sheets offer significantly higher strength than both marine aluminum and glass fiber sheets. While glass fiber sheets are stronger than most aluminum alloys, they still fall short of carbon fiber's strength. | |||

| Comparable Thickness | Due to its lower strength, thicker material is required to achieve the same strength as carbon fiber or glass fiber sheets. | Can be much thinner while still providing equivalent structural strength, due to its superior tensile strength. | Requires a thickness greater than carbon fiber but less than aluminum to achieve comparable strength. | |

| Example | If a marine aluminum sheet is 3 mm thick, a comparable glass fiber sheet might need to be 2 mm, while a carbon fiber sheet could be as thin as 1 mm to achieve similar structural strength. | |||

| Summary | High density, relatively lower strength, but good corrosion resistance and workability. It’s suitable for applications requiring cost efficiency and corrosion resistance. | Lowest density, highest strength, and can provide the most strength with the least thickness. It is ideal for high-performance marine applications where both weight and strength are crucial. | Falls between aluminum and carbon fiber in terms of density and strength. It is more cost-effective than carbon fiber and is suitable for applications needing a balance of performance and cost. | |

In marine applications, the choice of material depends on specific performance requirements, budget, and environmental conditions.

It is also important to note that Aluminium construction is done separately for each unit and additional units take almost the same time as the first unit. Construction in FRP may re-utilize some sections of the mould and would be a slightly quicker for additional units. The Carbon Fibre moulds allow for easy repeat use for all moulds and hence result in the quickest time for construction of additional units.